Bagasse paper making is currently one of the methods of producing paper. Bagasse can serve as a raw material for packaging paper, newsprint, paper containers and tissues instead of wood. It can be acquired in an eco-friendly way and the pulping process is relatively mild, making it a new raw material with development potential for paper making and more. This article will introduce bagasse and its applications, and describe methods of making paper from bagasse along with its advantages and disadvantages.

What is Bagasse?

Sugarcane has high sugar and water contents, so the juice extracted from them can be used for producing sugar or bioethanol. After squeezing, the fibers eventually left are called “bagasse”. Bagasse was originally used as a burning fuel and compost, but it has low combustion efficiency due to the water and carbon-rich substances (in a considerable amount) that it still contained. Moreover, it needed to ferment before being used for large-scale composting. In this age of environmental protection, scientists and enterprises have started to seek other methods of utilizing bagasse in order to reduce the amount of waste as well as possible pollution.

For the benefits and frequently asked questions of bagasse, please see the article: What is bagasse? 6 Benefits of Sugarcane Bagasse for Food Packaging.

What are Bagasse Products?

At present, common bagasse products include eco-friendly tableware and food-grade packaging. Other applications have been developed as well, such as:

- A substitute for cement: Bagasse can be added in concrete and partially substitute cement. This will enhance the strength of concrete as well as reduce the usage of cement, from which a large amount of carbon is emitted.

- Feed in agriculture and animal husbandry: After adding nutrients to improve palatability and provide nutrition including protein, bagasse can be a source of cellulose in mixed feeds.

- Papermaking: Same as wood, bagasse is rich in fibers and can be made into tough paper through fiber reconstruction during pulping.

- Ethanol after fermenting: Yeasts can decompose bagasse by hydrolysis, and the ethanol produced in the process may be provided to the industry and transportation for use.

- Solid fuel after machining: Compounding and mixing waste including scrap paper, plastic, and textiles according to their characteristics will improve burning efficiency. Thus, this waste can be sent to power plants for use in fuel rods.

It is widely applied in every industry.

What is Bagasse Paper and the Products?

Bagasse paper not only is yellower, but also harder and less bright. Therefore, it rarely serves as normal white writing or printer paper. Rather, it is mostly used as packaging paper, newsprint and paper containers. Different from other common wood for paper making such as blue gum, pine, eucalyptus, birch and cedar trees, bagasse contains a large quantity of piths, and these piths will result in lower paper quality and obstruction in paper making machines. Hence, piths must be separated from bagasse in advance, which makes the process of bagasse paper making more complex than normal paper.

How is Bagasse Paper made?

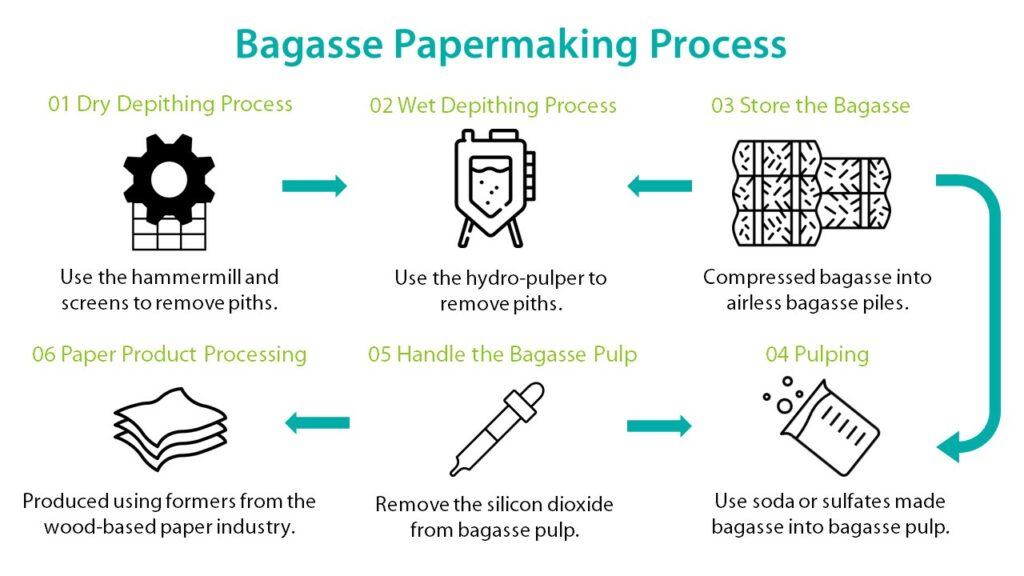

Use the dry depithing process to remove piths in bagasse initially

A dry depithing system consists of a hammermill and screens. The bagasse will be broken into pieces in the hammermill and separated from piths through sieving screens. After the dry depithing process, more than 20% of the piths will remain in the bagasse, so a wet depithing process is required to further reduce the quantity of piths in the bagasse.

Use the wet depithing process to further remove piths in bagasse

The wet depithing process is usually implemented at the time when bagasse pulp is about to be put into the paper making machine. The bagasse will be put into the hydro-pulper, completely soaked and broken at a concentration of 2% to 2.5%. Afterwards, the remaining 30% piths can be further removed. During this process, water can be recycled and reused.

Store the bagasse

Bagasse is a by-product of sugarcane. As a result, the supply volume of bagasse can change based on the harvest of sugarcane and demand in sugar production. In some regions, sugarcane can only be harvested around 6 months a year, so storage is required to adjust bagasse volume and stabilize the supply. Bagasse that underwent wet depithing will be compressed into airless bagasse piles with bulldozers or other machines. In most cases, this bagasse can be stored for up to 12 months. With reduced air exposure, it is able to maintain high brightness and keep the yellowness low after a long storage time.

Pulping

Bagasse is made into bagasse pulp before paper making, usually through the reaction of soda or sulfates at 90°C to 180°C temperatures (this depends on the process method). This process is similar to the normal pulp made from wood, but the lignin in bagasse reacts better than that in wood. Thus, the concentration of additional reactants and the temperature for preparation can be kept lower than in normal wood pulp.

Handle the bagasse pulp

Bagasse pulp contains silicon dioxide, which can damage the machine during the subsequent paper making process if not removed. For this reason, chemical solutions can be added to precipitate silicon dioxide and further remove it. Other than that, just like making paper from wood pulp, bagasse pulp has to be bleached using oxygen or oxides. However, the chemicals added in bagasse pulp during bleaching are less than those in wood pulp, and water can be recycled and reused for some bleaching methods. Hence, bagasse pulp is relatively friendly to the environment.

Make bagasse pulp into paper products by machining

The machined bagasse pulp is similar to the broadleaf wood pulp in terms of nature. It is formed with two of the equipment frequently used in the wood-based paper industry: fourdrinier formers and twin-wire formers. Paper formed would be compressed, dried, and turned into sheets by machines, and then serve as paper materials for any application after cutting and packaging.

The Advantages of Bagasse Paper and The Differences with Regular Pulp (Recycled Paper)

Bagasse paper has the following advantages:

Eco-friendly and reusable source materials

Bagasse paper’s source material comes from bagasse, making it a by-product of bagasse machining. Making paper from bagasse helps solve the issue of handling agricultural waste and gives bagasse, which would otherwise be buried or burned, a new lease of life and a chance to create more value. On the other hand, the traditional pulp requires deforestation while afforestation can destroy local ecosystems. Moreover, wood has a growth cycle longer than that of sugarcane, which takes 3 to 5 years or more.

The length of the fibers gradually becomes shorter during the recycling and renewal of paper. Thus, despite the use of recycled paper, new virgin pulp needs to be continuously added in every recycling process in order to maintain the tensility of the paper produced. During the re-manufacturing of recycled paper, energy consuming machines and chemical agents are required to separate the ink and plastic lamination from the paper, and this process might cause even more pollution.

Non-requirement of long-distance transport for materials

Sugarcane is usually planted in a specific area on a regular basis. After harvesting, it is delivered to the sugar refinery for sugar making. As long as the bagasse paper mill is established near the sugar refinery, the carbon emission and cost of material transport can be reduced. Unlike wood, which needs to be sent from the place of deforestation to paper mills in other regions, or even requires overseas transport.

Less pollution during the manufacturing process

Additional chemical agents as well as bleaching using oxygen or oxides are needed when plant fibers turn into paper pulp. On the other hand, bagasse fibers react better than wood, so they require a lower temperature and do not consume too many chemical substances when pulping. Not only that, but the water consumption is also lower than the traditional paper pulp and the recycled paper.

A harder texture

Bagasse fibers are shorter and can be damaged during the depithing process. However, they have thicker cell walls and are thus harder in texture than normal wood pulp. This makes them a suitable raw material for corrugated fiberboard and tissues.

Lower costs for materials and production

The major source of materials for bagasse paper is the by-products of sugar production. Many sugar refineries even must pay waste management companies to help dispose the waste, so these materials are almost free to get. Moreover, in modern days when forest-based carbon sinks are especially valued, enterprises have to the wood verified by credible international organizations (e.g. the Forest Stewardship Council (FCS)) in order to fulfill ESG obligations. As a result, the price of the wood conforming to sustainable development rises, causing a wider gap between the costs of wood-based and bagasse paper.

In addition, energy consumption and the costs of purchasing chemical substances can be reduced by lowering the temperature and chemical usage during the production process. Furthermore, pollution emissions can also decrease. This helps avoid carbon fee and tax imposition for carbon emissions as well as the cost of establishing preventive measures against pollution.

Safety and hygiene

The material of bagasse comes from food factories, which can ensure a sufficient degree of hygiene. Thus, bagasse paper can be used to make food containers. In addition, it is difficult to secure hygiene during the production process of recycled paper. As a result, some countries including Taiwan have established laws to prohibit the use of recycled paper on food container production.

The future of bagasse paper: A more eco-friendly choice

Based on the statistics provided by Statista, the total quantity of the paper and cardboard consumed around the world in 2021 was about 408 million tonnes, and the number is still growing. Containerboard, the major material of corrugated cardboard, accounted for the highest percentage. The volume of containerboard consumed in 2021 reached 178 million tonnes, and it is expected to surpass 220 million tonnes in 2031. If producing a tonne of paper needs an average of 17 trees, 34 billion trees will be cut down annually to make containerboard when its demand grows to 200 million tonnes. This is quite a shocking number, and it is global warming will possibly worsen as a result.

In addition, bagasse has a harder texture and is suitable for producing containerboard. According to the statistics made by Food and Agriculture Organization of the United Nation (FAO), the global production volume of sugarcane reached 1.9 billion tonnes in 2019, providing an abundant source of raw materials. Furthermore, the energy, chemical substances and water resources consumed in the production of bagasse pulp are less than wood pulp, making the former a more eco-friendly choice. At present, the technical difficulties are mainly in depithing, and further research is required in the future to overcome these issues.