【Interview with JuTian Eco-Material】Aren’t sugarcane straws really eco-friendly? Effective disposal of agricultural waste provides an alternative to sustainable living

Photo / 100% ZHI (/Plant/) Facebook page

At the beginning of this year (2018), the “plastic ban policy” was officially launched, and the EPA proposed a plastic reduction schedule of “banned for internal use in 2020, limited use by price in 2025, and fully banned in 2030,” the plastic products to be regulated include shopping bags, disposable tableware, single-use take-away drink cups and plastic straws. In Taiwan, where there are many hand-shaken beverage stores, the amount of plastic straws that come with the cups is frighteningly high. According to reports, Taiwan uses 3 billion plastic straws every year, and if you calculate 15 centimeters per straw, this amount is enough to circle the earth more than 11 times.

Photo reference / Taiwan Environmental Information Association

With the implementation of policies and the growing public concern for environmental protection, plastic products, which are considered to be the number one killer of environmental conservation, are facing a major challenge. Not only has the EPA specified that from July 2019, fast food chains and department stores are not allowed to provide disposable plastic straws, but more and more plastic alternatives are becoming known, and new options for plastic straws have come up, such as “glass straws”, “bamboo straws” and “stainless steel straws”. There are even NGO that care about the environment, such as the Islander Divers, which promote the idea of not using a straw and tasting the drinks directly, saying that “No straw marine life will thank you.”

“JuTian Eco-Material Co., Ltd.” (hereinafter referred to as “JuTian”), which has been researching eco-friendly materials since before the company was founded in 2013, also joined the proposal at this time, hoping to promote straws made of environmentally friendly materials and practice environmental protection together with all people.

Sugarcane Straws Are Serendipity, And The Research And Development Of Environmentally Friendly Materials Is Our Business

While it may seem strange to talk about “JuTian”, if you mention “Sugarcane straws“, you may be a bit impressed. The plastic ban policy has caused people to worry about “How to drink pearl milk tea? In July this year, the team launched the “100% ZHI (/Plant/)” brand, and launched the “sugarcane straws”, which attracted a lot of attention and discussion.

Photo / 100% ZHI (/Plant/) Facebook page

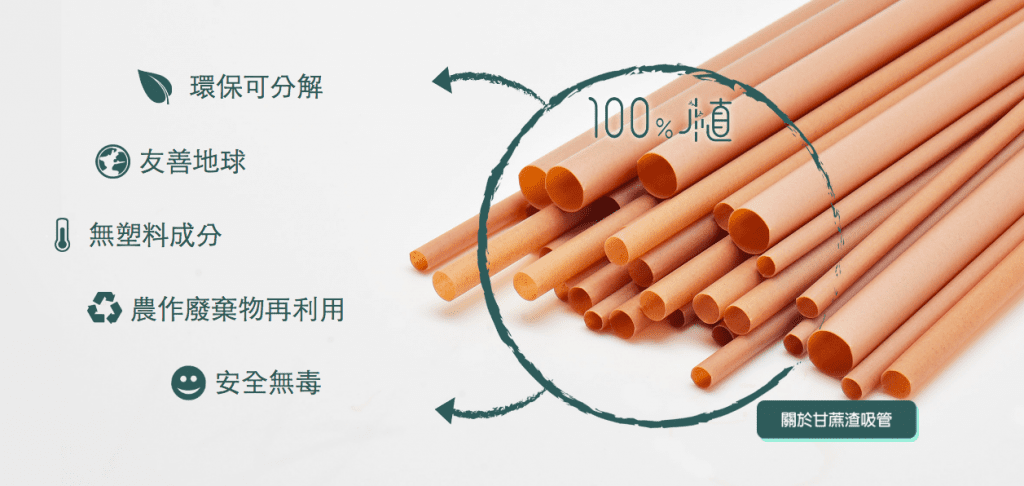

As the name implies, sugarcane straws are “made from sugarcane”. JuTian, which is well versed in the characteristics of straws, purchased bagasse belonging to agricultural waste from sugar producers, and pressed it into polymerized particles, mixed it with all-natural polylactic acid (PLA) as a sugarcane fiber adhesive.Open the mold to make sugarcane straws of different thicknesses, with straight or angle cut. “It was the right thing for us and the time was right, so we decided to launch the brand.” said JuTian’s CEO Bing-Han Tsai.

“The company’s main business is not straws, we focus on the research and development of environmentally friendly materials, so we are familiar with the materials, when the Director of the EPA Ying-Yuan Li proposed a ban on straws at the beginning of the year, we improved the original material recipe to make the straws you see now.” He also took out a sample pack of sugarcane straws, grabbed the plain colored straws and moved them close to his nose which can emit a caramel scent, when you actually drink the coffee, it’s the same as a normal straw,” he said. “The sugarcane straws can be produced by slightly adjusting the original materials and manufacturing process, using the original equipment for making plastic straws.”

Bing-Han Tsai, CEO of JuTian. Photography / Jing-Lun Ye

Not Only Sugarcane, But Also Bamboo And Coffee Grounds Have Been Reborn

JuTian purchases bagasse from a food factory specializing in sugarcane juice. For the food industry, bagasse is a real headache because the current regulations in Taiwan prohibit the reproduction of products from business waste, these bagasse have become “waste”, and it takes a lot of money and time just to find someone to clean them up. “We purchase these agricultural wastes at a low price and reproduce them into usable products, which not only helps companies achieve the goal of zero waste, but also achieves the effect of environmental protection.“

Like the sugarcane straws, JuTian also recently launched a “coffee grounds straw“, the finished product comes with the characteristics of the original material, the coffee grounds are dark brown in color and even have a strong coffee smell. “We are working with well-known coffee chains to recycle the coffee grounds from coffee shops into other items in a B2B (business-to-business) way to help companies achieve the goal of zero waste by turning the large amount of coffee grounds left over from the daily coffee sales at coffee shops into other products.

Coffee grounds straws. Photo / 100% ZHI (/Plant/) Facebook page

“The coffee shop owners’ eyes light up when they see our products!” Not only the straws, but also the branded eco-cups sold in the store, or the frequently used trays, or even the tables and chairs, to reduce the amount of waste discarded, so that the “circular economy” is no longer a slogan, “This is also a very marketing topics, more in line with the goal of business development, not only environmental protection and energy saving, but also increase the positive business image. Bing-Han Tsai said.

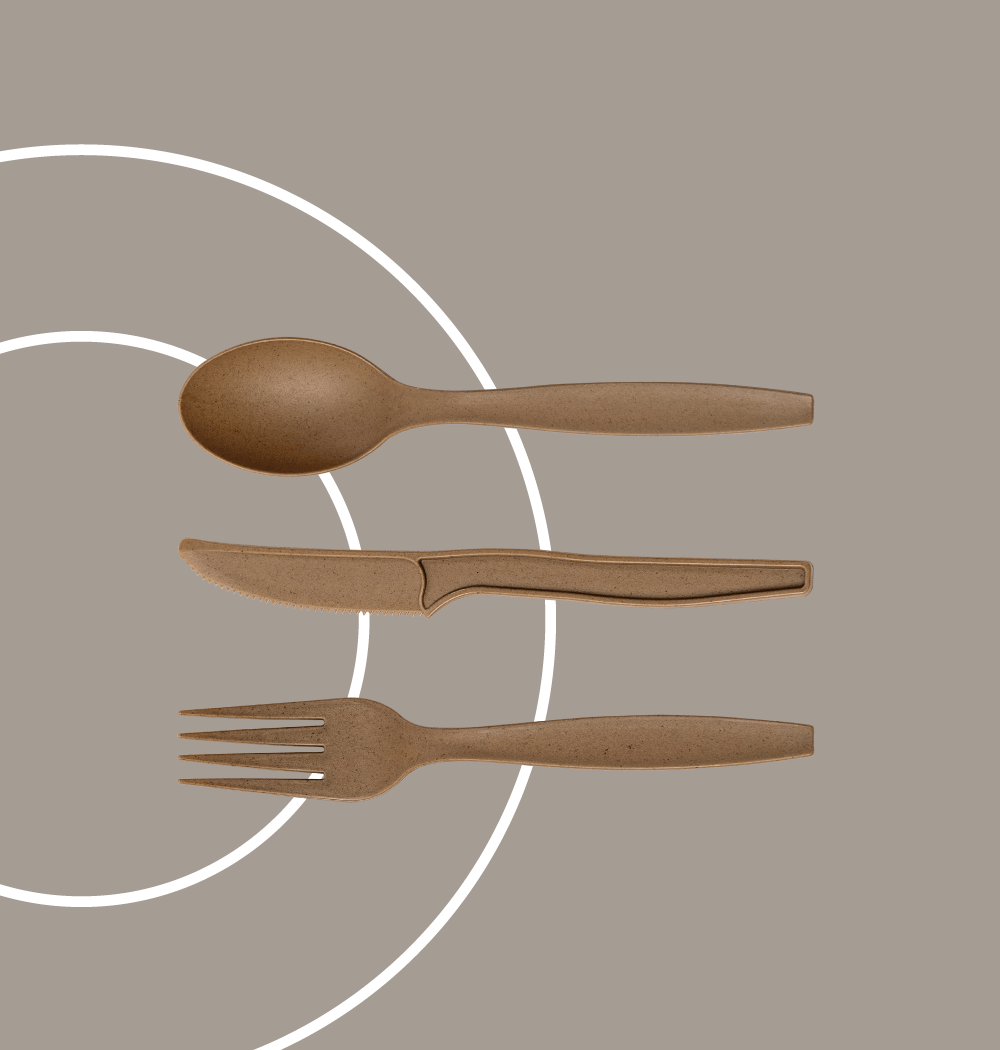

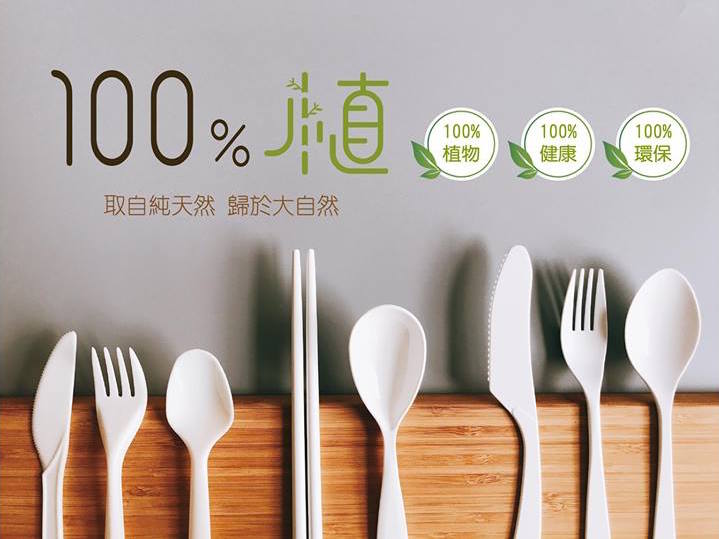

Besides straws, JuTian also offers eco-friendly tableware made of bamboo, such as knives, forks and plates. Bing-Han Tsai explained that in order to grow delicious bamboo shoots for human consumption, farmers must let the bamboo grow again every two years in the dense bamboo forests in the mountains of Taiwan. These waste bamboos, which have no place to be destroyed, have become treasures on the production line of JuTian’s environmental products.

Active Overseas, Environmental Protection Without Borders

There is another characteristic of agricultural waste, the main agricultural waste varies with the industrial type of different regions. For example, in France, where red and white wine are produced, a huge amount of grape pomace and wine dregs are produced. Therefore, JuTian is also looking farther and farther ahead, hoping to extend its reach abroad in the future and hope to make use of local agricultural waste to recreate products that fit local living habits, and to realize the ideal of environmental protection without borders with an international perspective and localized practices.

Therefore, JuTian has been actively participating in domestic and international exhibitions, such as the M&O furniture exhibition in Paris, where the “Materials Seminar” gathered French and international furniture designers. The founder of JuTian, Chien-Chung Huang, introduced the infinite possibilities of eco-friendly materials and how they can reduce the environmental impact. “Once designers know about these materials, they have an opportunity to choose and design their products according to the characteristics of these materials. For example, he originally used plastic for his cell phone case, but then he had the option of using eco-friendly materials,” Bing-Han Tsai said.

JuTian participated in M&O furniture exhibition in Paris to exchange experience with foreign designers. Photo / 100% ZHI (/Plant/) Facebook page

Interestingly, the most beneficial way of communicating with these international occasions to promote their products is not through translation or body language, but rather the United Nations’ 2015 “Sustainable Development Goals (SDGs)“. At a time when climate change is increasing and sustainable development is a common goal, the SDGs are quickly becoming the best common language internationally, “We are actively using renewable raw materials and designing decomposable products that are fully compatible with the SDGs concept.” (Reference: Albatrosses killed by garbage, sea turtles stuck in straws, how much longer can we consume the environment? /SDG-12 (Responsible Consumption and Production)

Since Taiwan’s regulations are not yet in place and not yet fully accepted by users, most of JuTian’s customers come from overseas, from Europe and the US to Australia in the southern hemisphere. “The concept of environmental protection is more common in Europe and the US, and is widely accepted by people in their daily lives, the promotion of the products is relatively smooth.” Bing-Han Tsai explained the difference in environmental awareness and practice between domestic and overseas.

It Is Not The Idea But The “Imagination” Has To Be Challenged

However, the road to sustainability has not been smooth. The first of many challenges faced by JuTian is the doubts from the OEMs. “For the manufacturers, it’s very difficult to change materials.” These OEMs originally used relatively stable plastic materials to produce plastic straws. Once the process conditions are set, no amount of plastic raw materials can be finished at one time. “But the natural material is not stable, its physical properties change every day, temperature, humidity and pressure will affect the process, for example, today set to 100 degrees, dry 20 minutes can make good quality straws, after a few days may have to adjust to 120 degrees, dry for an hour to produce smoothly.”

In response to this difficult situation, Bing-Han Tsai said that the team has adopted continuous training and hopes to build SOPs together with OEMs. “Only after everyone is familiar with the physical properties of raw materials can these environmentally friendly products be manufactured in large quantities like plastics, reducing costs and making them more acceptable and applicable to people.

Making eco-friendly, non-toxic, recyclable sugarcane straws is not easy. Photo / 100% ZHI (/Plant/) Official Website

In addition, B2B customers were not receptive to JuTian’s proposals from the beginning, so JuTian’s initial development proposals were frequently rejected. However, it is more like “unimaginable” than “unacceptable”, just as it is difficult for consumers to associate “waste bagasse” with “straws”. At first, we sent samples of raw materials to potential customers and told them, “We could develop any kind of product they wanted.” But after several rejections, we decided to mold the real finished product and tell them, “The cup you see here is made of bagasse, so that they will finally be curious and look forward to the product.”

Aren’t Sugarcane Straws Really Eco-Friendly? Incineration Or Burial Is Better Than Plastic

The third challenge to JuTian’s sustainability goals is that the general public is equally divided on the “Sugarcane Straw”. Some people believe that the change to an eco-friendly lifestyle can be achieved through sugarcane straws. Others say that there is no “biodegradable” waste recycling system in Taiwan, and doubt that these sugarcane straws mixed with PLA are in fact “still plastic” and “not that eco-friendly”. There are even professional medical maintenance knowledge platforms that call on consumers to think twice before buying.

In this case, Bing-Han Tsai said that JuTian is happy to see the discussion and rethinking of sugarcane straws, even if there are different opinions, that’s a good thing: “Maybe sugarcane straws are a start, and it’s good if you’re already used to bringing your own reusable straws; but for those who still use disposable straws, if you can give them a choice or a way to think about sustainability, you’ve achieved the goal of sugarcane straws.”

100% ZHI (/Plant/) also produces other products with eco-friendly materials. Photo / 100% ZHI (/Plant/) Facebook page

Bing-Han Tsai admits that Taiwan does not have a recycling system for biodegradable materials, unlike foreign countries where this type of product is a separate category for recycling, and after the public discards it, the officials will bury it in a site that meets high temperature and pressure conditions, so that it will be decomposed within 180 days. It is also true that PLA used as an adhesive is not suitable for disposal in traditional recycling factories, otherwise the melted PLA will cause adhesion effects on other plastic materials (such as PP) and seriously affect the plastic recycling process.

However, he also explained that the sugarcane straws made from 50% bagasse and 50% PLA are “better than ordinary plastic,” whether they are disposed of in an incinerator or buried in the soil. If sugarcane straws are incinerated, they will not produce toxic substances like plastic straws; if they are buried, “of course, they cannot be decomposed within 180 days, but they will still be biodepostable after one or two years”.

Expect More People To Invest In The Implementation Of The Original Purpose Of The Circular Economy

Bing-Han Tsai who keeps stressing that JuTian is “selling raw materials” and not straws, also said that JuTian will continue to work hard on the characteristics of raw materials and processes. We are looking forward to reducing our PLA dependence in the future, and to produce 100% plant fiber materials, so that the industry can use them to produce a variety of products and to maintain the original purpose of circular economy.

In the future, JuTian hopes to operate the enterprise with the concept of “satellite plant”, that is, JuTian, which specializes in material R&D, will distribute materials to different factories, so that they can make certain products separately, “such as straws and trays”, so that the production and sales of products can be more stable and commonly used. In addition, JuTian is looking forward to transferring its technology to foreign countries, so that we can set up recycling stations in the countries “where the waste materials are located, just like the factories in the world, so that the agricultural materials can be effectively reused”.

Source: https://npost.tw/archives/46635#