According to statistics from the World Bank, paper, food, and green waste account for more than half of the total waste generated by people. Composting is a great way to return these organic materials to the soil, thereby fostering a circular economy and lowering carbon emissions. At present, the main composting methods are industrial composting and home composting. Although the result is to convert organic matter into water, CO2, and nutrients, the decomposition process and conditions of the two methods differ considerably. This article will explain the differences between industrial composting and home composting, as well as the standards and certifications stipulated by governments and third-party organizations.

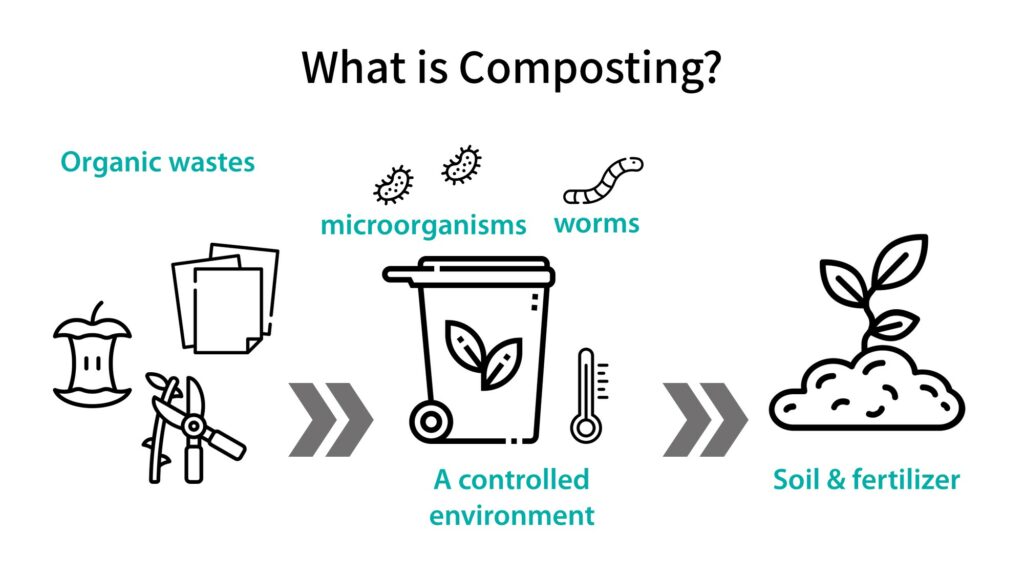

What is composting?

The process of converting people’s recycled organic wastes such as leftovers, paper, and green wastes into soil and fertilizer is referred to as composting. The process is carried out through microorganisms or worms. Unlike natural decomposition, composting is one of the waste disposal approaches performed by people in a controlled environment to ensure the composition of the compost, humidity, and air contact area to accelerate the rate of decomposition. At the same time, scientific material measurement and analysis have confirmed that decomposed substances created through composting are beneficial to Earth, making it an important waste disposal method for modern cities.

How does composting work?

Composting is divided into industrial composting and home composting. Industrial composting involves gathering organic substances to form large compost piles, adding appropriate ratios according to the type of raw materials, and supplementing oxygen to the compost pile by turning or aeration. At the same time, water is sprinkled on top of the pile to maintain about 50 percent humidity, allowing the compost temperature to increase naturally. The temperature in the center of the compost pile is the highest, sometimes exceeding 50°C, resulting in the fastest decomposition rate. The further away from the center of the compost pile, the lower the temperature. A well-maintained compost pile can decompose completely within several months, and the compost can be shipped to areas that are in need.

Home composting is conducted by individual homes. After collecting organic materials, the ratio is mixed according to the type of raw materials, and it is adjusted based on the conditions of the compost. The soil and fertilizer obtained from composting can be used for home gardening.

What is industrial composting?

How does industrial composting work?

Industrial composting is used for processing organic waste on a large scale. Organic waste sent to industrial composting facilities is screened first because every composting facility accepts different types of organic waste. Organic waste that can be composted will be divided into carbon-rich and nitrogen-rich categories and composted in an appropriate ratio. Currently, there are three most common industrial composting techniques:

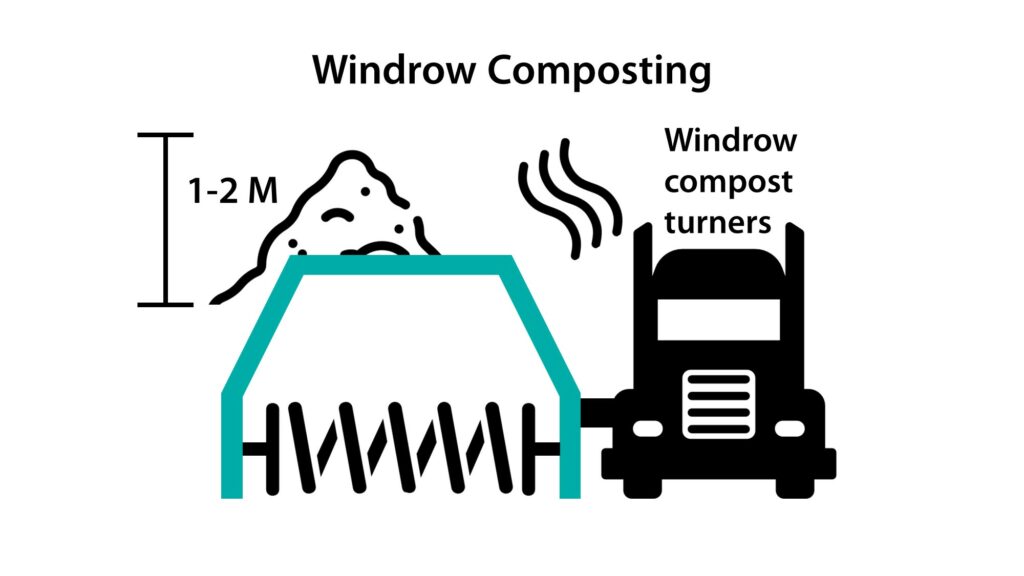

- Windrow composting

In windrow composting, the compost is stacked into one-to-two-meter long piles and exposed to the outdoor environment. During the composting process, windrow compost turners are used to turn the compost regularly. The inverted U-shaped windrow compost turners have a hollow chamber that allows the compost to pass through. When the turner is directly above the compost pile, compost will enter the turner, where the higher temperature compost in the center is turned to the outside, thereby ensuring every part of the compost pile is evenly exposed to air and balancing the decomposition rate.

Initially, the compost pile is turned at least once per week, and the frequency gradually decreases after a month. If the temperature is above 65°C or lower than 45°C, turning is also required. Turning is the costliest component of windrow composting and the key to determining composting speed. A well-maintained windrow compost pile can be completely decomposed within six months. If the turning frequency is low, it can still be decomposed into compost within a year for crop planting purposes.

- In-vessel composting

In-vessel composting is carried out in a closed environment. As it takes place inside a vessel, this method not only allows for better control of the odor generated by the compost compared to windrow composting but also saves space. Most containers are designed in the form of drums to facilitate turning; tunnels equipped with internal fans are also very common for in-vessel composting. A variety of monitoring equipment can be installed in the vessels to achieve more precise control of the composting temperature, air, and humidity, making sure that the temperature is sufficiently high to eliminate all the bacteria and weed seeds. In-vessel composting takes approximately 16 to 20 weeks to complete.

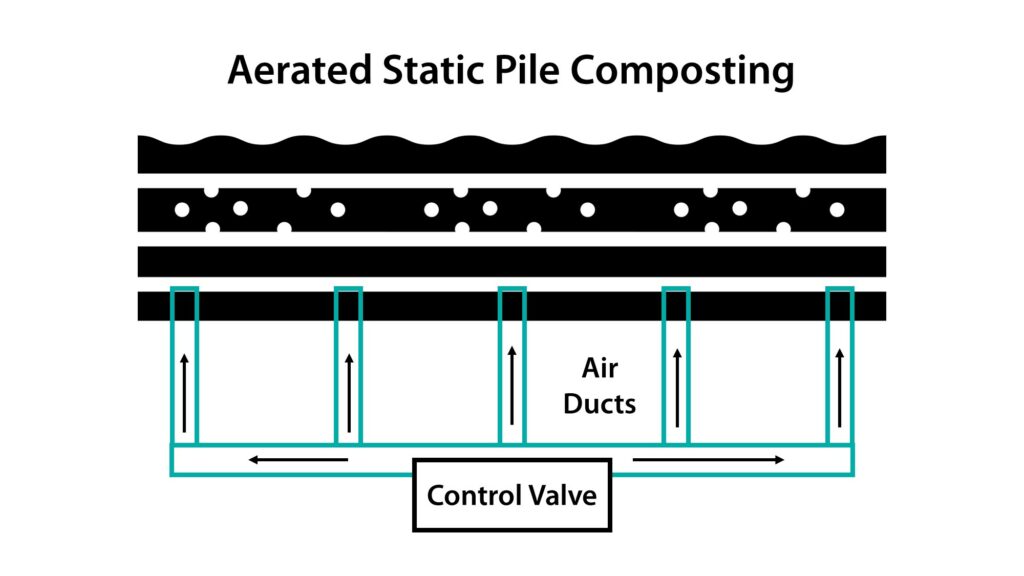

- Aerated static pile composting

Aerated static pile (ASP) composting loosely combines organic waste with fillers such as branches, sawdust, and shredded paper to ensure a free air space (FAS), allowing air to pass through with ease. At the bottom of the compost piles are air ducts that can blow air in or suck air out of the compost piles. Since the compost piles will not be turned and mixed, it is imperative to maintain various parameters such as the carbon-nitrogen ratio, moisture content, and FAS. Furthermore, at least 80 percent volatile solids are needed to ensure the biodegradability of the compost. During the composting process, an aeration control system is used to maintain a constant temperature, and complete decomposition will occur within three to six months.

Industrial compostable items

Industrial composts mainly consist of the city’s leftovers and green waste such as:

Branches and leaves from gardening.

Food waste, eggshells, fruits, vegetables, coffee grounds, sawdust, and shredded paper.

Agricultural waste, grapevines, vegetables, wheat stalks, and flower waste.

Some composting sites have a higher compost pile temperature for disinfection purposes, allowing them to process high-risk composting items such as animal manure, meat, fish, and fats that may contain parasites or harmful bacteria.

Industrial compostable certifications

The most common and credible industrial compost certification labels include:

- European harmonized standard: TÜV AUSTRIA OK compost INDUSTRIAL’s EN 13432 and DIN CERTCO DIN-Geprüft industrially compostable.

- American Society for Testing and Materials: ASTM D6400 or ASTM D6868’s BPI COMMERCIAL COMPOSTABILITY CERTIFICATION.

- Australian Compostability Standards: ABA Seedling Composting logo’s AS 4736.

Products bearing these labels can be decomposed in industrial composting facilities under adequate conditions. Since every industrial composting plant adopts different composting methods, not all industrial compostable products will be accepted. Please refer to local government announcements to determine if the industrial compostable products can be placed together in the compost bin for recycling.

What is home composting?

How does home composting work?

Home compost piles are created in individual homes on a relatively small scale to process household organic waste. If the ratio and humidity of nitrogen and carbon-rich materials are maintained properly, composting can be expedited, and odor from composting can also be minimized. Home composting is carried out via three approaches:

- On-site composting

Similar to the industrial composting approach but on a smaller scale, the composting materials are placed outdoors in the open space of the garden. During the composting process, a pitchfork or shovel is used to turn the compost pile while sprinkling water on top to maintain humidity. New composting materials can be added, but dry branches or leaves should be used to cover the fresh ingredients to avoid attracting insects or animals.

- Compost bin

Compost bins are similar to in-vessel composting, with the exception that home compost bins are smaller in design and are mainly cylindrically shaped or have built-in agitators to regularly turn the compost. One can also use garbage bins and wooden frames to build compost bins. This technique is suitable for most homes; even homes without gardens can compost in open spaces such as a balcony.

- Worm composting

If worm composting is used, worms will turn the fertilizer for people if a suitable temperature and humidity can be maintained. There is no need to pay attention to the ratio of carbon-rich materials such as paper and dried branches, and large quantities of leftovers such as vegetables or fruit peels can be added. The worms’ excrement is rich in nutrients, and the water seeping from the compost bin is called compost tea, which can be used as liquid fertilizer.

For more detailed home composting methods, please refer to the article Beginner’s Guide to Composting at Home: Five Steps to Get Started Quickly.

Home compostable items

Home compostable items include:

- Gardening waste such as branches, leaves, and withered flowers (must be pesticide and herbicide-free)

- Kitchen leftovers such as vegetables, fruits, and eggshells.

- Daily necessities such as paper, cardboard boxes, tea leaves, and coffee grounds. Note that they should not be chemically treated such as through bleaching or plastic coating.

- Products featuring home compostable labels such as renouvo’s home compostable bagasse straws and home compostable bagasse tableware.

- Note that proteins, fats, and manure cannot be used for home composting because the temperature of home composting cannot be increased adequately to decompose these materials or kill germs and parasites.

For more home compostable items, please refer to the article How to Compost at Home & Benefits of Home Composting.

Home compostable certifications

The most common and credible home composting certification labels include:

- Europe: TÜV AUSTRIA OK compost HOME, DIN CERTCO DIN Tested – Garden Compostable.

- Australia: ABA Home Compostable Verification.

Home composting is a relatively new concept that has been adopted by European countries and Australia. Each certification label uses multiple standards as the basis of verification: Australia’s AS 5810, France’s NF T 51800, and Europe’s prEN 17427. Products bearing these labels can be decomposed in regular home composting environments; there is no need to raise the compost temperature to a specific level. They can also be used as carbon-rich materials in home composting.

Home composting versus industrial composting

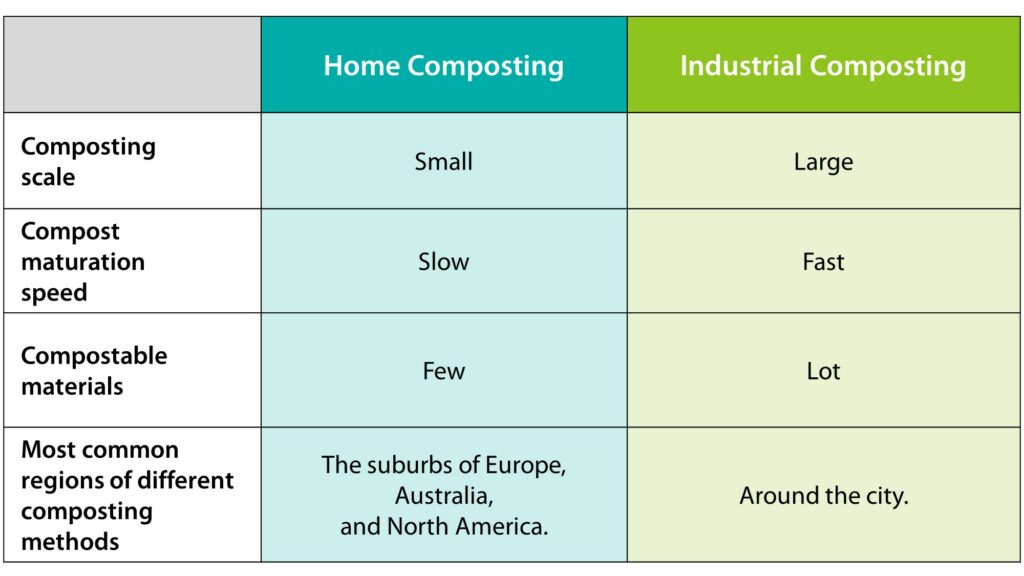

Although home composting and industrial composting are both ways to return organic substances to the soil, they possess significant differences in terms of composting scale, maturation speed, compostable materials, and the main regions where they are used. Their differences are listed below:

- Composting scale

Home composting is mostly small-scale and conducted in individual households, while industrial composting involves collecting organic waste from the entire region and composting it in large, professional composting facilities.

- Compost maturation speed

Thanks to good humidity, turning, temperature, and material ratio control, industrial composting offers superior speed and stability compared to home composting.

- Compostable materials

Home composting mainly processes household plant-based waste including branches, leaves, and flowers from gardening, as well as plant-based kitchen waste such as vegetables, fruit peels, and coffee grounds, and products that are labeled as home compostable. Since industrial composting increases the temperature to kill bacteria, it can process more materials including animal manure and products that are labeled as industrial compostable.

- Most common regions of different composting methods

Home composting is commonly found in the suburbs of Europe, Australia, and North America. Residents in these areas generally have backyards that allow them to create compost piles or composting bins to dispose of their organic waste. Industrial composting is common in cities around the world. The municipal management system will establish an organic waste recycling system to collect and transport organic waste from various firms to industrial composting plants around the city. Large-scale professional facilities are used to efficiently process more waste.

Are bioplastics compostable?

Bioplastics are made from renewable organic materials such as corn starch, bagasse, wheat stalks, and seaweed. Although these bioplastics are natural, some of the materials do not decompose easily, or chemicals are added during the production process, making them unsuitable for composting and not necessarily eco-friendly. One should observe whether the materials have obtained industrial composting or household composting certification labels to determine whether they can be composted.

A good time to grab home compostable tableware!

Both industrial composting and home composting are appropriate ways to process people’s organic waste. Since plastic waste does not decompose naturally and is not recyclable, many manufacturers nowadays are producing plastic substitute products using compostable materials. Examples include disposable straws or tableware. Using home composting-certified tableware ensures that it can be broken down naturally in most composting environments, thereby contributing to environmental friendliness.