People strive to achieve a circular economy with zero landfills. To accomplish this, the most important organic waste processing method is composting. Scientific aerobic composting was developed in the 20th century in the hope of replacing some of the chemical fertilizers while processing waste. As the technology has become more mature, people have begun to understand how to use various environments and materials to convert organic substances into humus in the most efficient manner. Furthermore, equipment is developed based on those conditions to conduct composting on a larger scale, endowing composting plants with a stable capacity to process organic waste and produce compost. This is referred to as commercial composting.

Besides commercial composting, in order to overcome the limitations of commercial composting, municipalities in many countries also encourage citizens to apply the principle of commercial composting using more accessible and affordable equipment to engage in home composting. With the advent of composting and plastic reduction trends, manufacturers are developing compostable products to achieve responsible production. How is commercial composting implemented? How is it different from home composting? Could products that claim to be commercially/industrially compostable be suspected of greenwashing? The article will attempt to address these issues to let readers gain further insight into commercial composting and products designed with compostability in mind.

What is industrial/commercial composting?

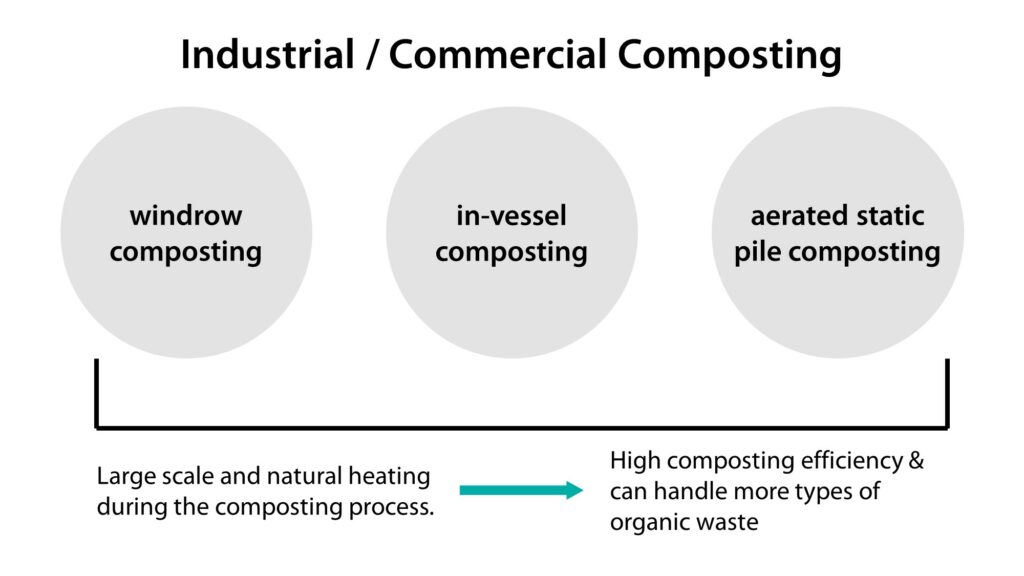

Commercial composting is also called industrial composting, a form of mass-scale and scientific composting. Examples include windrow composting, in-vessel composting, and aerated static pile (ASP) composting. Windrow composting involves stacking the compost into long one-to-two-meter piles, where windrow compost turners are used to turn the compost regularly, providing it with air and moisture. In-vessel composting involves placing waste in drums, pods, or concrete tunnels and mixing internally in a closed environment that is monitored at all times to regulate aeration and humidity. For ASP composting, ventilation ducts are embedded in the ground, and waste is loosely scattered over the ducts, where the air is blown into and drawn out of the compost pile to regulate aeration.

For more information on the three commercial composting methods, please refer to “Home composting versus industrial composting: How they work”.

Regardless of the type of commercial composting technique adopted, they all possess the same characteristics such as large scale and natural heating during the composting process. This is far more efficient than home composting, which takes place on a smaller scale and under room temperature as it is difficult to raise the temperature of the compost pile. At the same time, the former can process more diverse organic waste to convert the city’s organic and agricultural waste that was destined for landfills, thereby decreasing methane production. The final product, called humus, can be sold to farms or home gardens, making it an extremely important eco-friendly waste disposal method.

How does industrial/commercial composting work?

Step 1: Collect organic waste from community waste bins and farms

Organic waste processed by commercial composting comes from community waste bins and farms. A contract is signed with municipal administrations, community management agencies, or farms to regularly recycle their organic waste and transport it to commercial composting facilities for disposal.

Step 2: Categorize and sort organic waste

After organic waste is sent to the commercial composting facility, non-compostable materials, such as glass bottles, stones, petroleum-based plastics, and metal bottle caps will be sorted out manually or by a waste separator.

Step 3: Nitrogen-rich materials are crushed and mixed

Composting materials can be divided into nitrogen-rich and carbon-rich materials. Nitrogen-rich materials include fresh branches, leaves, leftovers, coffee grounds, tea grounds, egg shells, and so on. Commercial composting facilities with adequate heating and long composting durations can process a wider range of nitrogen-rich materials such as meat, bones, pet droppings, and small amounts of fat. The nitrogen-rich materials will be crushed and mixed into the equipment, where they are collected in preparation for the next step.

Step 4: Mix the nitrogen-rich and carbon-rich materials in an appropriate nitrogen-to-carbon ratio

Carbon-rich materials include sawdust, dried leaves, hay, paper products, and compostable products. The nitrogen-to-carbon ratio of compost that decomposes in the shortest time and produces the least odor is approximately 1:30. Commercial composting facilities mix these nitrogen-rich and carbon-rich materials based on past experimental data. Depending on the commercial composting method chosen, the mixed composting materials are placed into containers or piled up.

Step 5: Continuously monitor and adjust the humidity and aeration of the compost pile

During the composting process, commercial composting facilities will continuously monitor the composting conditions, adding water and turning the compost pile when necessary (air is blown into or drawn out of the compost pile in the case of ASP composting) to create high-quality compost within several months.

Step 6: Collect and sell the dark soil generated by composting

After the completion of the composting is verified through testing, the compost will be sold to individuals, farms, or municipal facilities such as parks to foster the growth of plants. The composting facilities that have been freed up will commence the next commercial composting project, repeating the cycle to dispose of organic waste.

Home composting versus industrial/commercial composting

Home composting

The definition of home composting: Organic waste generated every day is collected and converted into humus that can improve soil quality through small composting facilities at home or in the community. Home composting is divided into on-site composting by creating compost piles outdoors, compost bins, and worm composting. Since compost piles are smaller and do not increase in temperature naturally, this is considered room temperature composting, which has a slower decomposition speed and more stringent requirements for the decomposition of compost materials. Certification labels for products or materials that meet the conditions for home composting include TÜV AUSTRIA OK compost HOME, DIN CERTCO DIN Tested – Garden Compostable, and ABA Home Compostable Verification, which stipulate that at least 90% of the products or materials must decompose within 360 days in a home composting environment.

Industrial/commercial composting

The definition of commercial composting: Municipal or agricultural organic waste is collected and converted efficiently into humus through large commercial composting facilities. Due to the larger composting scale, commercial composting plants feature better aeration equipment that can increase the composting temperature to above 50°C. Consequently, they can quickly process more diverse organic waste. Certification labels for products or materials that meet the conditions for commercial composting include TÜV AUSTRIA OK compost INDUSTRAL, DIN CERTCO DIN-Geprüft industrially compostable, BPI COMMERCIAL COMPOSTABILITY CERTIFICATION, and ABA Seedling Composting, which stipulate that at least 90% of the products or materials must decompose within 180 days in a commercial composting environment.

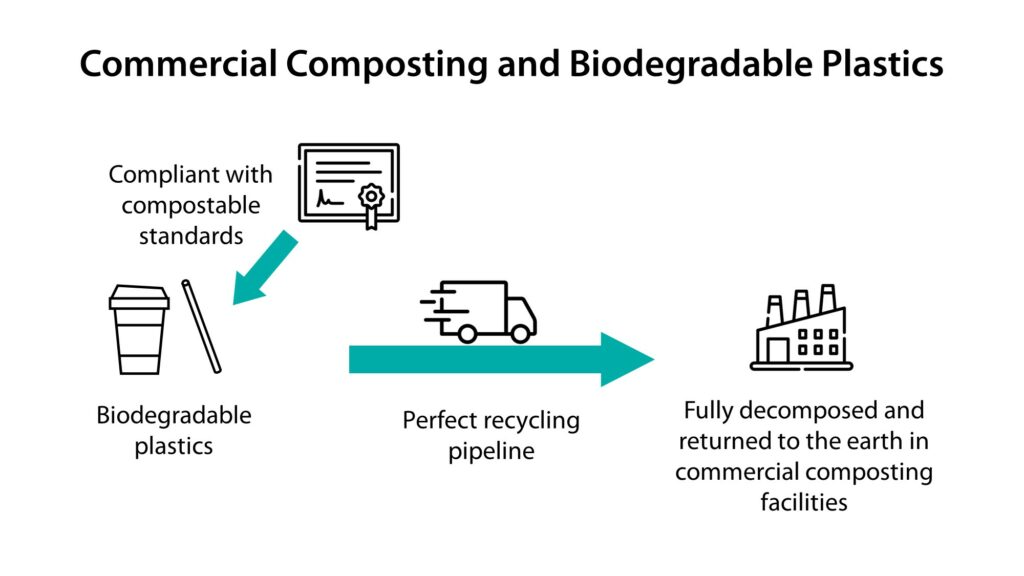

Understanding commercial composting and biodegradable plastics

People successively developed new materials in the 20th century known as biodegradable plastics to replace plastic. These plastics are different from oxo-degradable plastics that quickly break down into fragments because they can be completely decomposed by microorganisms and will not produce microplastics. However, it is not so easy to strike a balance between cost, product stability, and degradability. Commercial composting facilities offer better decomposition conditions and elimination/digestion systems for biodegradable plastics like PLA that require high temperatures to break down. The material facilitates the creation of a comprehensive recycling channel, so verification agencies have formulated decomposition standards for commercial composting environments, and countries have also stipulated laws and regulations to ensure that these biodegradable plastics can be broken down in commercial composting facilities, thereby creating eco-friendly plastic alternatives.

How to identify compostable products and packaging

Method 1: Look for the compostable certification

Compostable certification provides stringent testing standards to ensure that certified products and packaging can be completely broken down in an industrial or household composting environment and that only CO2, water, and nutrients are produced in the process, in turn protecting the compost pile from contamination. Pay attention to products that claim to be compostable and see if TUV, ABA, BPI, DIN CERTCO, or Compost are printed on them or their packaging. The label design and official website description of various certifications is provided below:

ABA – Commercial composting label (for seedlings) and home composting label (for recycling bins)

BPI – Printed with COMPOSTABLE for standard commercial composting certification

DIN CERTCO – Commercial composting (printed with INDUSTRIAL COMPOSTABLE) and home composting (printed with HOME COMPOSTABLE)

Method 2: Confirm if the processing method is specified

Some compostable products or packaging are made of natural materials, such as paper, or thicker home compostable materials. These compostable materials or products may not have applied for compostability certification because of cost considerations or their inability to be broken down in the specified time frame. However, when these products or packaging are shredded, they can be used as home composting materials in accordance with suggestions provided by local municipalities or waste disposal companies. Be aware that commercial composting facilities do not accept uncertified compostable plastics. If products made of compostable plastics are recommended to be composted commercially, but no indications are given as to how to dispose of the products and they have not obtained industrial or home composting certifications, there is a strong suspicion of greenwashing and consumers should avoid purchasing them.

What are commercially compostable products?

Currently, commercially compostable products mainly consist of bags and tableware. Five commercially compostable products are already available on the market:

Compostable garden waste bags

Of all commercially compostable products, compostable garden waste bags are most widely accepted by commercial composting facilities. Many municipalities distribute free compostable garden waste bags to citizens to collect their garden waste and place it on the roadside, where it will be transported to a commercial composting facility for disposal.

Compostable food packaging

Untreated brown bags and certified compostable food packaging can be commercially composted. However, if they are used to contain excessively greasy food, some commercial composting facilities will request the public to dispose of them as regular trash because of the problem associated with breaking down the excess fat.

Compostable cups

Due to hygiene considerations, plastic cups cannot be produced with recycled plastic, hence the material is not recyclable. On the other hand, it is difficult to recycle most paper cups that contain petroleum-based coating, so many enterprises such as Starbucks utilize compostable plastic cups or change the plastic coating of their paper cups to a compostable material, so that the cups may be commercially composted directly after use.

Compostable straws

Due to their light weight and thinness, it is difficult to recycle straws. Using compostable materials to produce straws takes advantage of their light weight and thinness to optimize their compostability. This means that the straws can be sent directly to a commercial composting facility after use.

Compostable tableware

Compostable tableware is used to replace disposable plastic utensils. For commercial composting facilities that can process leftovers, the compostable tableware can be placed into the compost collection bin together with leftovers and sent to a commercial composting facility for disposal.

Why sustainable? Three benefits of using compostable products

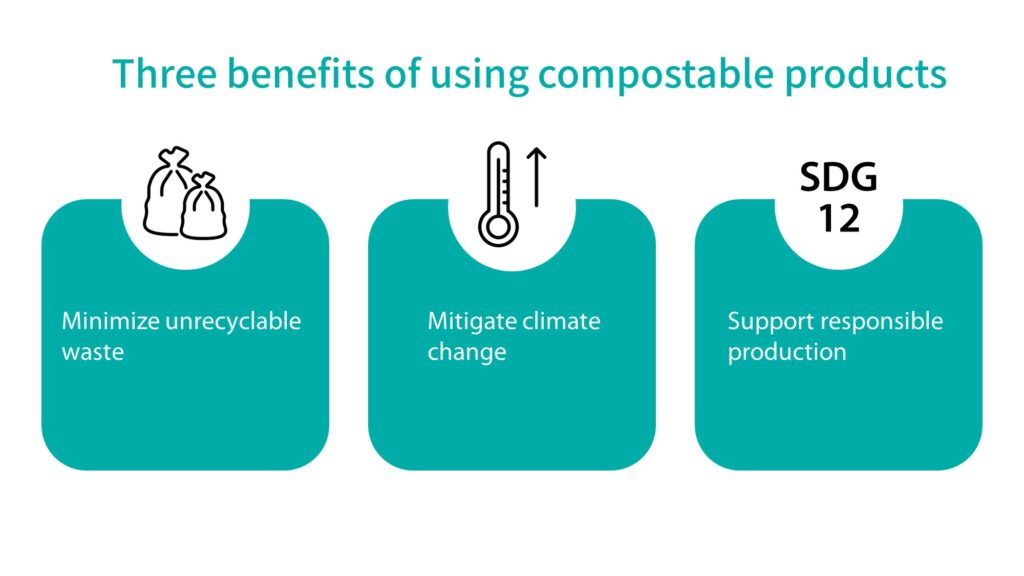

People in modern society are faced with a multitude of environmental problems such as resource depletion, climate change, air pollution, and water pollution. If we do not strive to achieve sustainability, the Earth may not be habitable for humans within the next several decades. Using compostable products is one way to contribute towards sustainability. The three major benefits of using compostable products are outlined below:

Minimize unrecyclable waste

Compostable products can be completely broken down via composting after use and returned to the environment as natural substances. In doing so, unrecyclable waste is reduced to prevent the relentless construction of landfills and incinerators that can contaminate the air, soil, and water.

Mitigate climate change

Compostable products can replace petroleum-based plastics, which consume a great deal of resources during the excavation, refining, and production process. Using compostable products lowers energy consumption and GHG emissions.

Support responsible production

Compostable products come with clear instructions for composting and disposal so that users can understand how to dispose of them to achieve a circular economy. Using compostable products and sorting them for recycling can support responsible production in everyday life.

Regarding the importance of responsible production of SDG12, please read this article: WHAT IS GOAL 12? RESPONSIBLE CONSUMPTION AND PRODUCTION.

Commercial composting risk: Greenwashing

Commercial composting is a brand-new organic waste processing technology that provides people with a more eco-friendly and efficient way to manage organic waste adequately while lowering GHG emissions. Decent decomposition conditions also allow materials that could not be broken down in the past to be decomposed via commercial composting. However, as a matter of fact, even products that have been certified as industrially compostable may not be accepted by commercial composting facilities in every region. For instance, Portland, Oregon, USA, expressly states on the government’s official website that it is prohibited to place compostable products (except for BPI-certified compostable bags) in the green compost trash bins. Consequently, if you are disposing of waste in these areas, please choose home compostable products first. An additional benefit of compostable products is that the raw materials are usually renewable, hence it is possible to confirm whether more eco-friendly materials and processes are adopted, such as agricultural waste recycling and remanufacturing or low-carbon processes. If the product’s carbon label is provided, consumers can compare whether the carbon emissions are lower than that of their plastic counterparts. These are some ways you can avoid purchasing environmentally unfriendly and greenwashing products.